Published : 2025-09-11

With the development of technology, today's construction sites are not necessarily the dusty places they once were, but rather automated and intelligent scenes integrating high technology.

Modular buildings, sky building machines, construction robots... The application of these technologies has greatly improved construction efficiency, making the "mass production of houses" no longer a fairy tale.

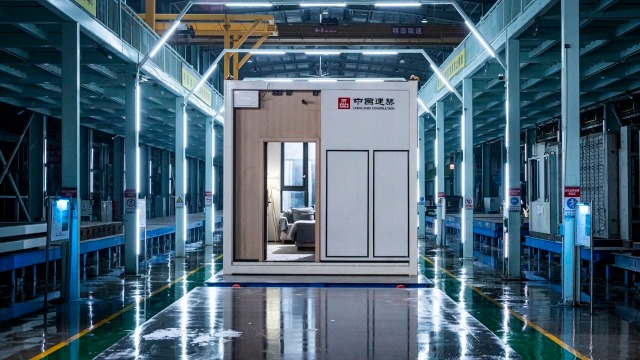

Modular building: Building houses like building cars

In recent years, modular building has often been mentioned in the news. So-called modularisation means that a majority of the construction work is completed in a factory beforehand, and then container-like rooms are assembled together like building blocks.

This way, not only can the decoration, plumbing, and electrical systems be pre-installed, but even the furniture can be fully equipped.

After the prefabricated modules and components are transported to the construction site, only tasks such as connecting the modules, treating the seams, and connecting the pipelines are needed to efficiently complete the construction of the entire building.

Compared with traditional construction methods, modular building can shorten the construction period by one-third to one-half.

A construction company in south China's Guangdong Province stated that modular buildings can reach a height of 40 storeys, with a factory prefabrication rate of over 90%; the total construction cycle can be shortened by about 50%, and it reduces construction waste by 50% and carbon emissions by 75%.

Guangdong is one of the main production bases for "Modular Integrated Construction" components. Hong Kong, with its geographical advantage, was the first to apply modular building products from Guangdong in various projects such as office buildings, school dormitories, public housing, and private buildings.

According to statistics, from January to May 2025, the total value of modular building exports from Guangdong to Hong Kong was approximately 1.39 billion RMB, a 2.3-fold year-on-year increase.

Not just in Hong Kong, modular building products have also been promoted and applied overseas, including in more than 20 countries and regions such as Iceland, the United States, and Australia.

Read more: Huizhou builds Hong Kong's first "Light Public Housing"

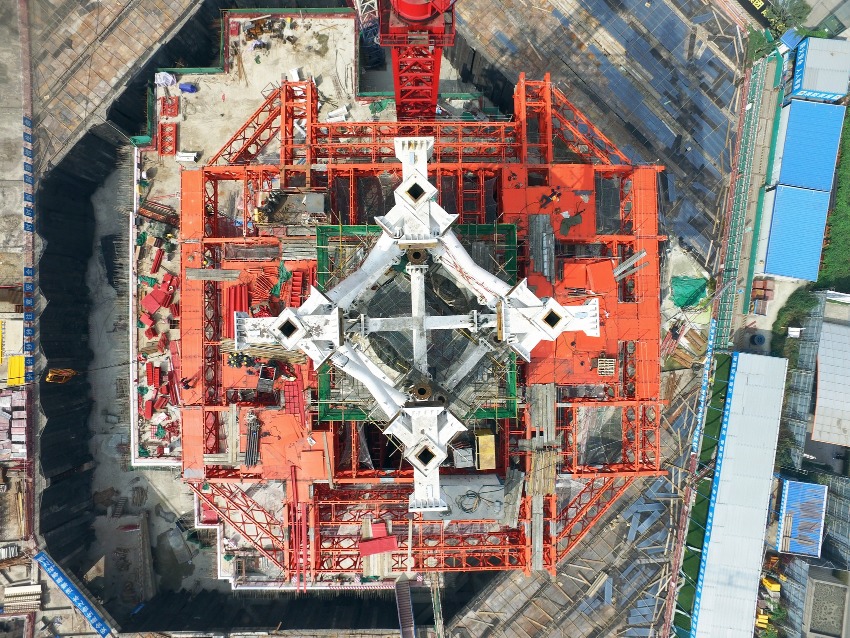

Sky building machine: Build 1 storey in 5 days

If modular building is about moving the construction site into the factory; then the sky building machine is about moving the construction site into the air.

A building machine is a new type of intelligent equipment integrated platform that integrates concrete machines, construction lifts, accompanying tool and equipment rooms, monitoring systems, and temporary water and power supply systems, forming a working space for material storage, production, and fabrication.

It is like an efficiently operating, enclosed factory where workers can carry out streamlined operations, including multiple processes such as rebar tying, formwork installation and removal, and concrete pouring, allowing the construction of a structural layer to be completed in about 4 to 5 days; it is currently being used in the construction of skyscrapers.

What are the benefits of moving the construction site into the sky? Some projects are located in the city centre, where the site is small and construction materials cannot be stored for long periods; construction workers need to continuously transport construction materials up to high altitudes.

In such cases, using a sky building machine can reduce the space required for storing construction materials and alleviate the pressure of vertical transportation on the site.

Furthermore, the building machine can form an enclosed, safe workspace, and its steel platform structure can serve as a sturdy protective enclosure, ensuring that working at height is as safe as working on the ground.

Read more: China's "sky building machine" leads the world

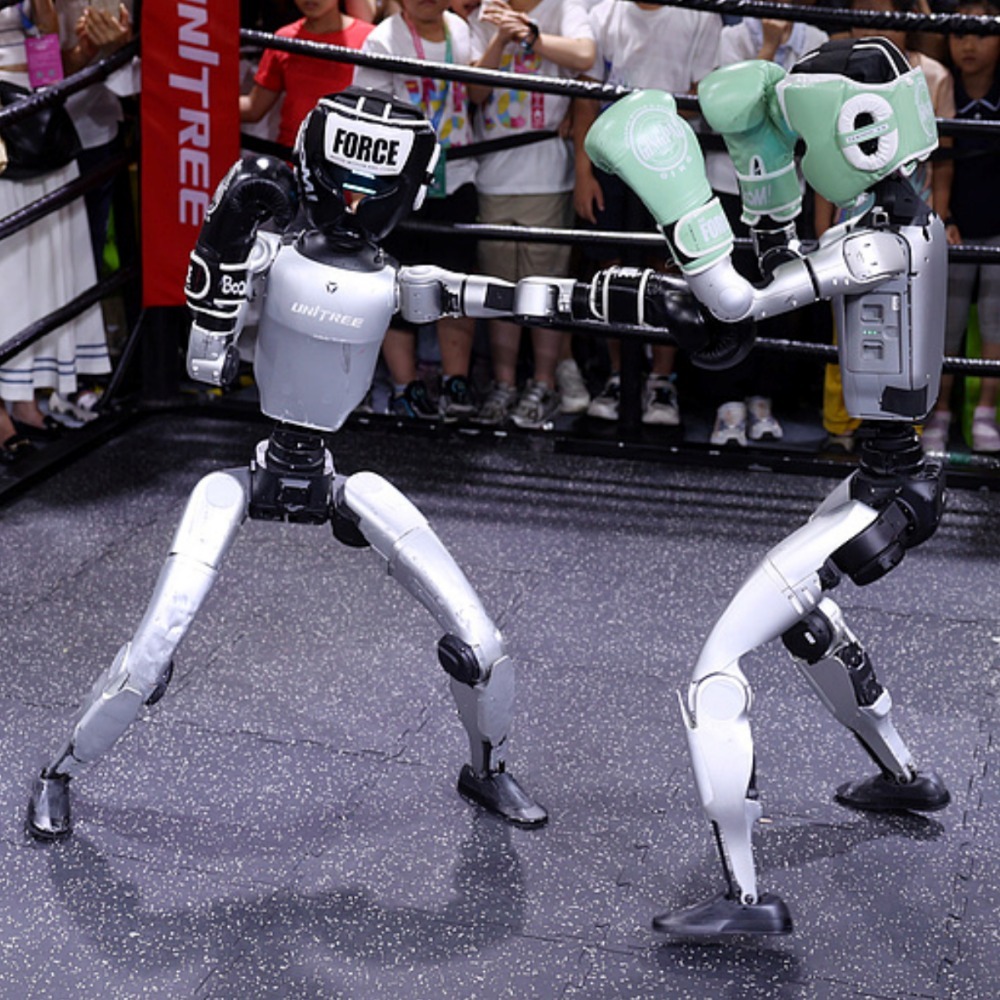

Construction robots enhance construction efficiency

To improve construction efficiency, automated mechanical equipment is essential. Nowadays, many complex and time-consuming processes rely on the help of robots.

For example, measuring, floor levelling, tile laying, mortar spraying, and measurement quality inspection are all performed with precision with the help of robots.

For example, a surveying robot uses advanced digital laser scanning equipment to perform a complete laser scan of a three-dimensional space and uses AI to take measurements automatically. It only requires one person to operate for a single room, which can be completed and have its data uploaded in 1.5 minutes.

A floor levelling robot improves the flatness of an area by 95% compared to traditional manual construction, and can also eliminate the need for a second levelling, allowing for direct tile laying.

These types of robots are also very common in Hong Kong. For example, the construction robot "Tri-Prime", which is currently used in public housing projects, integrates multiple functions into one.

It can use lasers to perceive its surroundings and, through calculation, plan the optimal construction path; it can also collect dust while sanding, keeping the construction site clean and tidy; and it can also be remotely operated by workers to perform spray painting, protecting workers' health.

Housing construction is related to the people's livelihood and well-being. The development and application of high technology will inevitably improve construction efficiency and benefit the public.

Read more: Independently developed construction robots debut in Foshan